Many different electronic circuits and systems have been designed and developed at MARLEX Engineering. We provide a full range of electronic circuit design services to our clients to assist in developing an idea into a prototype and eventually into a product. A few examples of our own in-house electronic designs are shown below.

- Electronic Circuit Design

- LED Replacement For Fluorescent Tube

- C-Back™

- Tractor Trailer Lighting & Signal Tester

- Electronic Valve

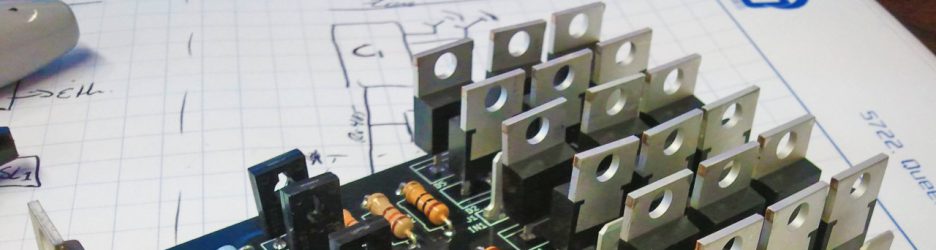

Electronic Circuit Design

For customers with an idea for an electronic product or device, MARLEX Engineering provides services to design, build and test custom electronic circuits. Our skilled circuit designers can develop analog, digital and mixed signal electronic circuits. Our circuit designs take advantage of the latest technologies and components currently on the market including specialized ICs and off-the-shelf modules. For circuits that require microcontrollers and Digital Signal Processors (DSPs) our experienced programmers will develop the software and firmware that is required to operate the device. For all our designs we supply detailed schematic diagrams and a complete Bill of Materials (BOM).

We also design and layout the Printed Circuit Boards (PCBs) for the circuit and supply all the files and documentation that are necessary for manufacturing the boards. We can arrange to have the boards manufactured and populated with components and once prototype circuits have been made we will thoroughly test them.

Throughout the process we work with our customers to make improvements and adjustments to the design if required.

For customers who already have an existing circuit or product we can assist with:

- Modifications to the circuit.

- Improvements to the circuit.

- Diagnosing faults and problems in an existing design and recommend fixes.

LED Replacement For Fluorescent Tube

MARLEX has developed a drop-in LED lamp module to replace fluorescent tubes. This breakthrough patented technology can be used in both specialty and general lighting applications. The F32T8 Tube LED Replacement Module utilizes the existing size, shape and connections of a standard four foot F32T8 fluorescent tube and can be operated either directly from the mains supply or by the ballast that is currently in the fixture. This allows for a simple retrofit of existing F32T8 lighting installations without the need to rewire the fixture.

Our LED tube-replacement technology provides the advantages of:

- Increased lamp life

- Wireless RF based ON/OFF and dimming control

- Energy Savings through occupancy management and daylight harvesting applications

- Environmentally friendly alternative to mercury-based fluorescent lighting

- Shatter resistant lamp design

- Lower total cost of ownership

The MARLEX design team is currently adapting our LED lamp drive technology to other applications, including HID Lamp replacement.

C-Back™

C-Back™ is an intelligent back-up system for the Light Duty and Passenger Vehicle market. This patented, ultrasonic-based technology alerts the driver to objects in the path of the vehicle both before and during reversing.

In an independent evaluation the Grote Obstacle Detection System was rated “Best Buy” by Consumer Reports magazine, and was also named as one of the best 50 products of 2003 by Heavy Duty Trucking Magazine.

- Reports obstacles that may be hidden in the vehicle’s blind spot.

- Uses three separate detection zones behind the vehicle.

- Sound and LED indicators to warn the driver where and whenever an obstacle is detected.

- Using C-Back™ helps reduce the possibility of damage to commercial and privately owned vehicles during reversing.

- System automatically activates when the vehicle is placed in reverse.

- Designed for clean, neat installation on existing vehicles.

- Rugged, waterproof sensor is designed to operate in extreme temperatures resistant to rain, snow, ice, slush, road salt, and carwashes.

- Performs a self-check each time it is activated to detect:

- Sensor obstruction (by mud, dirt, snow or ice buildup on sensor).

- Connection of sensor to control unit.

- Power to the Control Unit.

Tractor Trailer Lighting & Signal Tester

The Trailer Tester is an extremely rugged, durable and valuable tool for testing the wiring and lighting systems on commercial truck trailers to help find and eliminate any electrical circuit problems. It is designed for use in facilities that manufacture, refurbish or test trailers. The trailer is simply plugged into the tester and then using either a convenient wireless remote or the front panel buttons the operator can switch power to any combination of the six individual circuits in the trailer:

- Clearance, Sidemarker and I.D.

- Left-Turn Signal and Hazard

- Right-Turn Signal and Hazard

- Tail Lamps, Marker Lamps and License Plate Illumination

- Stop-Lamp and ABS

- Continuous Power

Easy to read LED displays aid with testing/troubleshooting by showing the current drawn by the circuit as well as open and short-circuit faults.

Trailer Tester Features

- Wireless Hand-held Remote – circuits can be activated from anywhere around the trailer – saving time and money

- Heavy-duty Design:

- Internal protection circuitry and resettable circuit breakers prevent damage to the tester if it is connected to a short-circuit.

- No mechanical switches on the main unit that could wear out or break – advanced circuitry senses the operator’s fingers through a solid panel of high-impact plastic.

- A rugged piece of equipment made for use in a dirty environment and built to last.

- Easy to Move – the entire tester and battery are mounted on a wheeled cart so it can be quickly and easily moved around the work area.

- User-friendly – a powerful tool yet simple to use.

- Multiple Power Sources – accepts power from a 120VAC source or a 12V automotive battery, or both.

- Built-in Charger – internal power supply automatically charges the battery.

- Standard Interface – uses an industry standard SAE J560 cable and a 12V automotive battery.

- Modular – the main control unit can be used as a stand-alone tester by simply lifting it off the cart.

- Auto Power-off – preserves battery life if tester is left on.

The Trailer Tester is available for purchase through ProQuip International under the name RT300 Remote Tester.

Electronic Valve

Our in-house R&D efforts have led to the successful development of a patented low-power piezo-electronic controller. Our technology is ideal for use in power critical applications where low cost and high reliability are of primary concern.

Together with the mechanical design team from Veltri Technologies we have integrated our controller into an innovative Electronic Valve Positioner. Targeted for use in the chemical processing industry, our initial product offering is a self-powered 4-20mA current loop controlled version of this positioner. HART programmable derivatives of this technology are currently being developed.